Bussiness InfoOperation

Overview

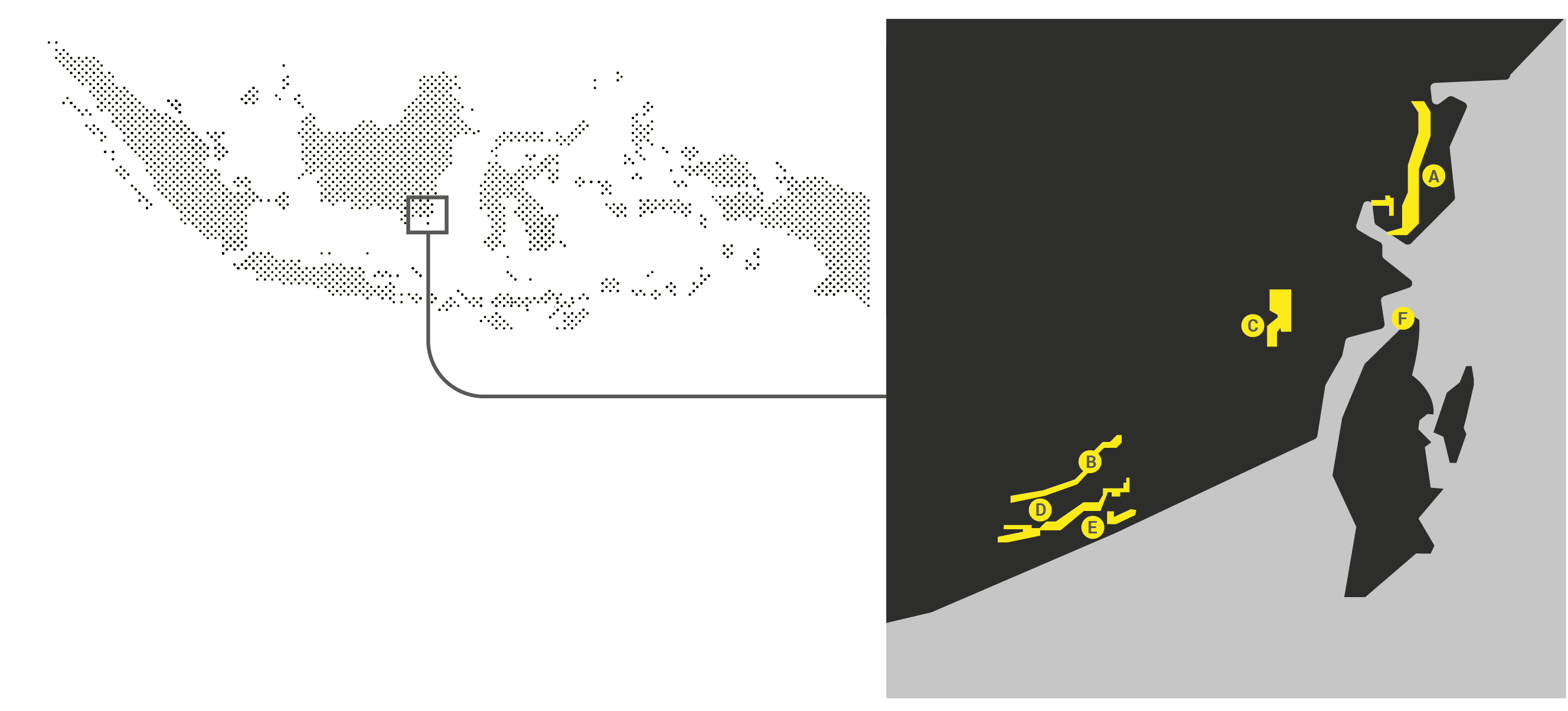

SITE AREA:

A. Senakin Mining Site

B. Satui Mining Site

C. Batulicin Mining Site

D. Asamasam Mining Site

E. Kintap Mining Site

F. North Pulau Laut Coal Terminal (NPLCT)

Arutmin is one of the Government of Indonesia’s contractors engaged in coal mining. Arutmin’s mining operation area consists of five active sites and one coal terminal that is spread across three districts in South Kalimantan; Tanah Laut, Tanah Bumbu, and Kotabaru.

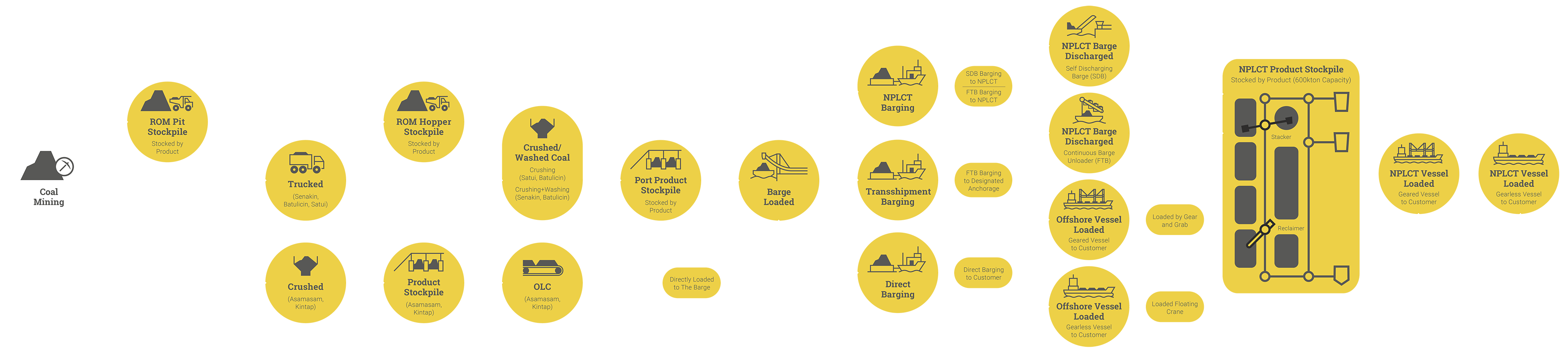

Coal Flow

Production

PT Arutmin Indonesia’s activities are operated at its five sites; Senakin Site, Satui Site, Batulicin Site, Asamasam Site, Kintap Site, and one coal terminal, North Pulau Laut Coal Terminal (NPLCT).

- SENAKIN SITE

- SATUI SITE

- BATULICIN SITE

- ASAMASAM SITE

- KINTAP SITE

- NORTH PULAU LAUT COAL TERMINAL (NPLCT)

The Senakin Site is the first coal production area operated by Arutmin. The journey to Senakin Site from Banjarmasin (350 km) can be reached through several alternatives: a road trip, a combination of road trip followed by ferry or speed boat crossing, or journey by air.

The Senakin Site produces bituminous type coal or high-calorie coal. For its processing, all produced coal is taken to the coal washing area. The coal washing amenity is focused to reduce the ash levels by separating coal from impurities. The washed coal products are targeted to contain 12% of ash. The coal washing facility holds a production capacity of approximately 430 tons/ hour.

The production capacity today at Senakin Site reaches 1.3 million tons/ year. Optimization of coal production at the site is also made on thin coal with a thickness of 20-40cm. This attempt supports the implementation of conservation to meet the mining regulations set by the government.

The Satui Site is one of the first sites operating since the establishment of PT Arutmin Indonesia. Exploration activities at Satui Site started from 1983 to 1987, while infrastructure development and trial-mine started from 1987 to 1988. Commercial mining activities began in 1990 with PT John Holland as the main contractor. In 1995, mining activities were run solely by PT Arutmin Indonesia. In 2000, an alliance with Thiess Contractor Indonesia occurred, and in November 2001 a divestment took place from BHP Billiton to PT BUMI Resources Tbk.

Coal processing at Satui Site is done at Muara Port with production capacity up to 10 million tons/ year. Muara Port is equipped with several facilities such as metal detectors, magnet tramps, automatic cross belt samplers, laboratories, continuous infrared temperature sensing, and dust suppression systems. The coal produced in Port Muara owns its largest market share in Japan, India, China and the Philippines.

Batulicin Site began operating in 2003 in the Ata Block and the Mangkalapi Block with a production capacity of 900 thousand tons of coal. Batulicin Site expanded its area by opening the Mereh Block in 2008 and the Sarongga Block in 2011. Batulicin Site once reached its peak production of 9.5 million tons/ year. Today, its production in a stable at approximately 6.0 million tons/ year from a total production capacity of 15 million tons/ year.

Batulicin Site holds a large amount of coal resource and reserves. Its operational area that is spread out results in diverse coal quality, from lignite to bituminous. The characteristic of the coal is classified as young coal with low calories and high HGI, which both become a challenge for the Batulicin Site. This challenge is responded by implementing the basis of good mining technical principles and implementation of conservation in all aspects of mining. The short hauling distance makes the Batulicin Site own an economical value even though it produces low-calorie coal.

Reclamation actions are made in line with mining activities. Reclamation is done for the stone pile area outside the mine as well as inside the mine. Aside from reclamation in the active mining area, the Batulicin Site is also preparing activities to support the closure of several areas of the site that are completed.

The location of mining activities at Asamasam Site is administratively located in Asamasam Village, Jorong District, Tanah Laut Regency. The Asamasam Site production reaches 8.0 million tons/ year producing low-calorie (sub-bituminous) coal products.

Asamasam has received BIRU ratings for the Company Performance Rating Evaluation Program (PROPER) awarded by the Provincial Government of South Kalimantan and the Ministry of Environment. In 2011, the Asamasam Site received an ISO 14000: 2004 SNI 19-14000: 2005 certificate for its Environmental Management System.

Infrastructure built in the Asamasam Site includes the Coal Processing Plant (CPP), administrative office, workshops, B3 and LB3 warehouses, and Fuel Tank. The placement of each infrastructure is positioned in strategic locations for easy access to all locations at the mine to support a smooth mining operation.

The Kintap Site began operating in November 2011 with a production capacity of 500 thousand tons/ year. Kintap Site continued to increase its production capacity with production reaching 8.5 million tons/ year of coal. The coal at the Kintap Site is categorized as an ecocoal type containing low sulfur. Besides Asamasam Site, the Kintap Site also uses Overland Conveyor (OLC) to improve the efficiency in coal transportation.

The construction of North Pulau Laut Coal Terminal (NPLCT) began in 1992 and started its first commissioning and shipment in 1994 with a total shipment of 4.5 million tons of coal. NPLCT as an international terminal owns qualified technology facilities to support the process of unloading and loading coal, such as:

Jetty Unloading (barge berth)

NPLCT owns two Jetty Unloading (Barge Berth) serving the unloading process.

The first Jetty Unloading is used for Self Discharging Barge (SDB) with an unloading capacity of 4000 tph.

The second Jetty Unloading is for Flat Top Barge (FTB) that with a capacity of 3,000 tph for the unloading process.

Stacker

The Stacker functions to move unloaded coal from the barge to stockpile with a capacity of 4,000 tph.

Reclaimer

Reclaimer functions to collect coal from the stockpile to the conveyor for the loading process with a capacity of 4,000 tph.

Shiploader

Shiploader functions to transport the coal from the conveyor to the vessel for the shipment process with a capacity of 4,000 tph.

Jetty Loading (Main Berth)

Jetty Loading (Main Berth) functions as the vessel’s backrest in the loading process with the vessel’s maximum capacity of 120000 DWT.

To achieve zero contaminants, the NPLCT Port is facilitated with four metal detectors and two magnet separators for the coal loading and unloading process.

Port Regulations

Port Regulations outline the rules and procedures necessary for the smooth and efficient operation of the Arutmin’s Ports and Its facilities. These regulations apply to Individuals, organizations, or companies buying or selling coal through the ports, as well as to those responsible for bringing vessels to the ports for loading.

Additionally, these regulations govern the relationship between the ports and their users, ensuring efficient vessel turnaround and overall port efficiency. Arutmin reserves the right to modify these regulations at the sole discretion of Arutmin.